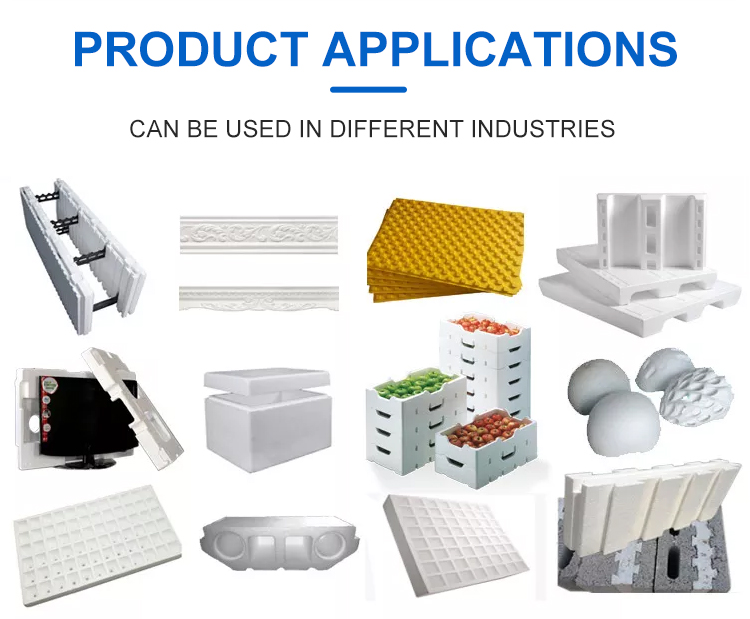

OPTEM Series Full- Automatic EPS Shape Moulding Machine

Product Categories: EPS Shape Moulding Production Line

Product display: Semi Automatic EPS Shape Moulding Machine , EPS Shape Moulding Machine MAnufacturer, EPS Machine,EPS Shape Machine

Product description: The machine adopts PLC control with completed function which is convenient to operate. Each instrument, valve, electrical appliance are all high quality durable components with reliable performance.

Machine Description

OPTEM Series Full- Automatic EPS Shape Moulding Machine Introtuction:

1. High strength frame :

Made by high quality steel plate (Thickness 25mm). After welding and pre-machining ,machine main frame is processed with stress relief annealing treatment Pipe inner side is processed with zinc spraying. Whole machine is processed with abrasive blasting(sandblasting),electrostatic spray and anti-corrosion treatment, ensure the equipment non-rust, non-corrosion and non-deformation in working.

2. Safety design

With safety designing, if it’s in overload state, the machine will stop automatically.

When the machine begins to work , four safety door(stainless steel) will be locked automatically.

3. Smooth working and easy maintenance

1) Adopts metal support legs and platform which is more convenient to inspect and maintenance.

2) Equipped with advanced guide sleeve and self-lubricating bearings changing system(no need to add lubrication oil, and the bearing life time is at least one and half years), it solved the problem for sleeve and bearings’ changing while with improved lubrication

4. Steam control system

Main steam pipe is equipped with steam pressure-reducing & stabilizing valve , ensure steam working stably and save more energy. Two steam lines for moving mold, two steam lines for fixing mold. During production, one steam line is open, another line is doing slight adjustment automatically according to the mold pressure. This will save the energy ,ensure little steam fluctuation, good for making high quality products.

5. Pressure adjusting system:

Adopt 12 road pressure adjusting system, ensure the optimized consumption of steam,air, cooling water and material feeding . Any practical pressure(steam, air, cooling water or clamping pressure for hydraulic mold ) lower than the setting value, the machine will alarm and stop automatically to ensure products’ quality.